The Product and Service

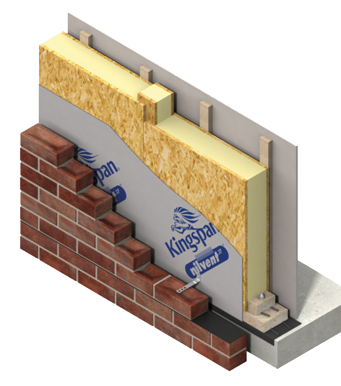

The product is a Structural Insulated Panel (SIP) and construction process that replaces traditional timber stick-framing and gives much higher insulation ratings for the same thickness.

It can be used for walls and the roof. In New Zealand KnightBuilt backs this up with a full cut-to-design, pre-fabrication and installation service that delivers you a moisture-proof-clad outer building shell for a single price.

The Kingspan TEK® panels are available in two sizes:

- 142mm thick with an insulation R rating of 5.1

- 172mm thick with an insulation R rating of 6.4

The Kingspan TEK® panels are a certified passive house building component by the Passive House Institute - see the Documents page for certification details.